03 Jun Pneumatic Press Machines

Pneumatic Press Machines: The Advantages and Applications

In the world of manufacturing and automation, the Pneumatic Press Machines stands out as a versatile and reliable tool. Kamtronix Automation, a leader in industrial solutions, offers a range of pneumatic presses that cater to various applications. This blog will delve into the advantages and applications of pneumatic presses, providing you with a comprehensive understanding of why they are essential in modern manufacturing processes.

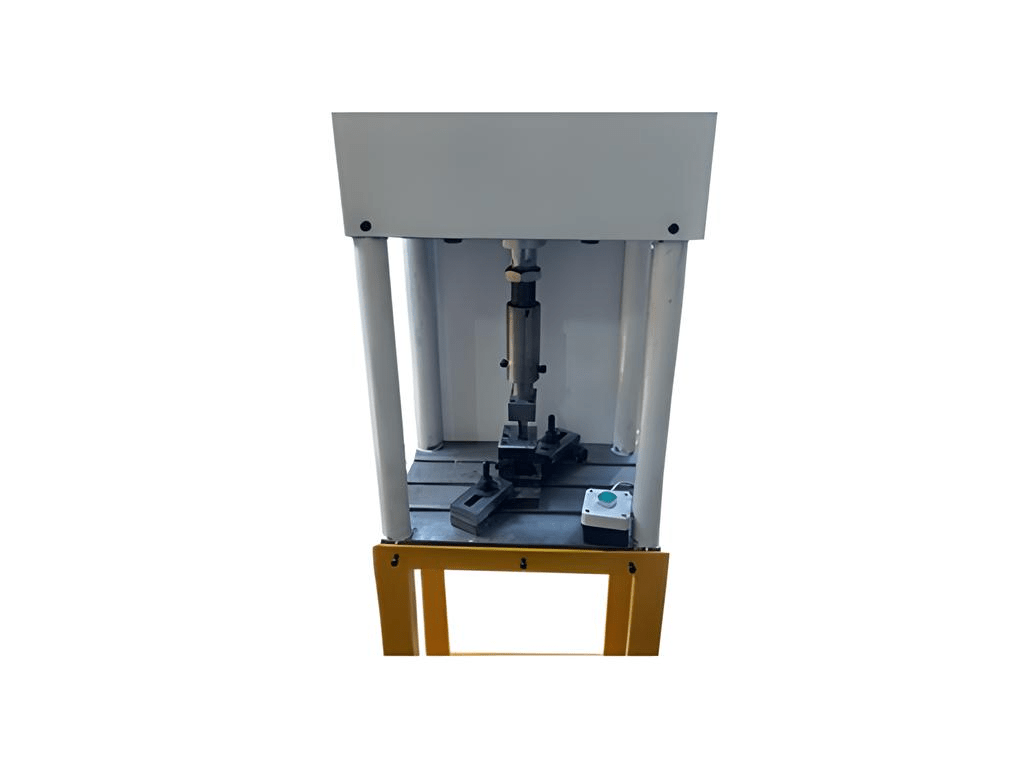

What is a Pneumatic Press?

A Pneumatic Press Machines is a type of press machine that uses compressed air to generate a force for pressing operations. This machine is widely used in various industries due to its efficiency, precision, and cost-effectiveness.

Importance in Manufacturing

Pneumatic presses play a crucial role in manufacturing, enabling businesses to perform tasks such as assembly, stamping, forming, and riveting with high accuracy and speed. They are particularly valued for their ease of operation and minimal maintenance requirements.

Advantages of Pneumatic Presses

High Efficiency and Speed

One of the primary advantages of pneumatic presses is their ability to operate at high speeds, significantly increasing productivity. The use of compressed air allows for rapid movement of the press, making it ideal for high-volume production environments.

Precision and Control

Pneumatic presses offer excellent precision, allowing for consistent and accurate results. This precision is crucial in applications that require exact tolerances and repeatability. The ability to control the force and speed of the press ensures high-quality outputs.

Cost-Effective Operation

Compared to hydraulic presses, pneumatic presses are more cost-effective to operate. They require less maintenance and have lower operational costs due to the simplicity of their design and the use of readily available compressed air.

Versatility

Pneumatic Press Machines are versatile machines that can be used for a wide range of applications. They can be easily adjusted to perform different tasks, making them suitable for various manufacturing processes.

Safety Features

Modern pneumatic presses come equipped with advanced safety features to protect operators and ensure safe operation. These features include emergency stop buttons, safety guards, and two-hand control mechanisms.

Applications of Pneumatic Presses

Assembly

Pneumatic presses are widely used in assembly operations to join components together. Their precision and speed make them ideal for assembling parts in automotive, electronics, and appliance manufacturing.

Stamping

Stamping is a common application of pneumatic presses, where the press is used to shape or cut materials such as metal, plastic, or paper. This process is essential in producing parts for industries like aerospace, automotive, and consumer goods.

Forming

In forming applications, pneumatic presses are used to shape materials into desired forms through bending, stretching, or drawing. This process is crucial in manufacturing components for construction, automotive, and furniture industries.

Riveting

Pneumatic presses are also used in riveting operations, where they apply force to rivets to join materials together. This application is common in the aerospace, automotive, and electronics industries, where strong and reliable joints are required.

Punching

Punching involves using a pneumatic press to create holes or shapes in materials. This process is widely used in metalworking, electronics, and packaging industries to produce precise and clean cuts.

Clinching

Clinching is a joining process where a pneumatic press is used to interlock materials without the need for additional fasteners. This technique is commonly used in sheet metal fabrication and automotive manufacturing.

Embossing

Embossing involves using a pneumatic press to create raised or recessed designs on materials. This process is often used in packaging, printing, and decorative industries to enhance the appearance of products.

Conclusion

Pneumatic presses are indispensable tools in modern manufacturing, offering numerous advantages such as high efficiency, precision, cost-effectiveness, and versatility. Kamtronix Automation’s range of pneumatic presses is designed to meet the diverse needs of various industries, ensuring reliable and high-quality performance. Whether you are involved in assembly, stamping, forming, or any other manufacturing process, a pneumatic press can significantly enhance your productivity and quality of output.

No Comments