01 Dec High-Precision Hook Bending Machine by Kamtronix Automation

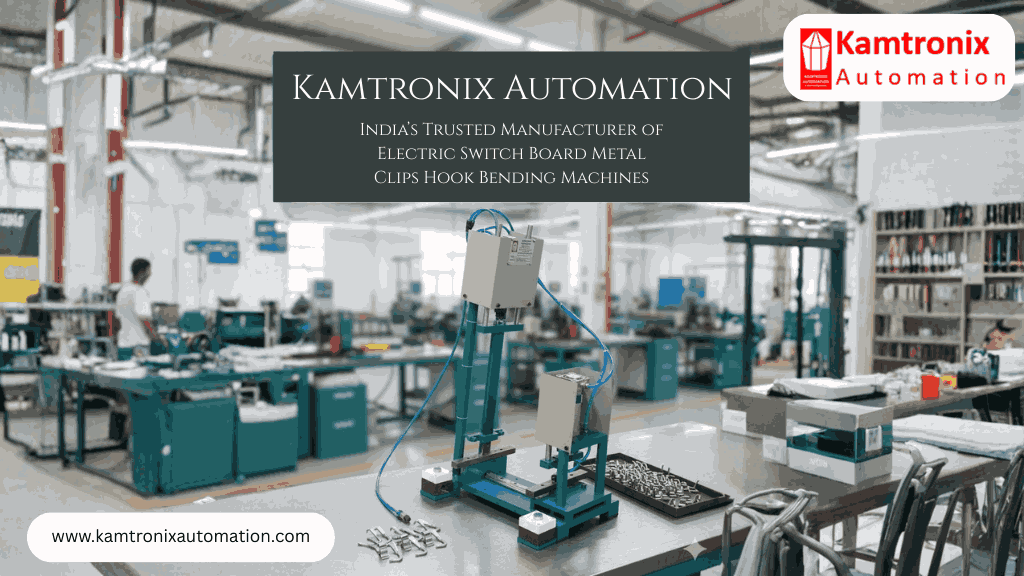

Kamtronix Automation — India’s Trusted Manufacturer of Electric Switch Board Metal Clips Hook Bending Machine

Introduction

The electrical industry moves fast—and manufacturers who want to stay competitive need equipment that keeps pace. That’s where Kamtronix Automation comes in. Known for engineering reliable and high-performing machinery, Kamtronix has become a go-to Electric Switch Board Metal Clips Hook Bending Machine manufacturer from India.

Whether you’re producing small batches or running large-scale operations, the quality of your clips and hooks directly affects the safety and reliability of your electrical switchboards. Kamtronix machines are designed to ensure perfect consistency, clean bending, and long-term durability—no guesswork, no manual inaccuracies.

In this blog, let’s explore what makes Kamtronix Automation’s bending machines stand out and why so many manufacturers across India trust them.

Why Precision Matters for Switchboard Clips & Hooks

Clips and hooks might look small and simple, but in the electrical industry, they play a big role. A tiny defect can lead to poor fitment, loose connections, or even switchboard failure.

Here’s why precision bending is crucial:

- Ensures consistent shape and dimensions

- Reduces product failures in the field

- Improves installation experience for technicians

- Keeps overall quality standards high

- Avoids unnecessary rework and scrap

Kamtronix Automation focuses heavily on delivering machines that provide repeatable results—every single time.

About Kamtronix Automation

Kamtronix Automation is known for its engineering excellence and customer-focused approach. As a leading Electric Switch Board Metal Clips Hook Bending Machine manufacturer from India, they design machines that combine modern automation with robust construction.

A quick look at what sets them apart:

- In-house R&D and design team

- PLC-based automation for smarter bending cycles

- Strong and durable machine build for long-term use

- Customizable setup for different clip/hook designs

- User-friendly interface suitable for both new and experienced operators

Whether you’re upgrading from manual bending or expanding an automated production line, Kamtronix offers solutions for all scales of manufacturing.

Key Features of Kamtronix Hook Bending Machines

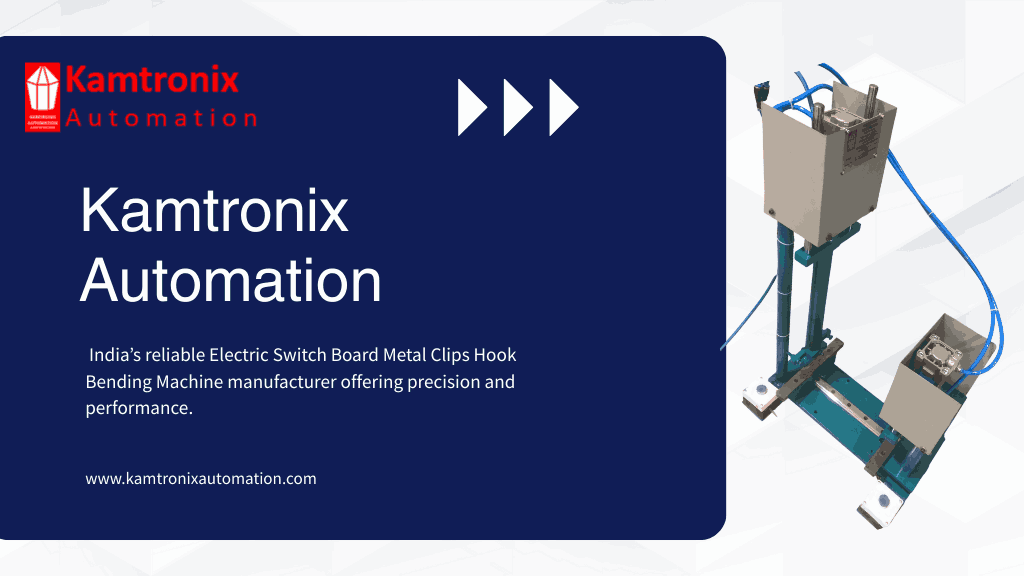

Kamtronix machines stand out because they combine technology, durability, and ease of use. Here are some core features:

1. High-Precision Tooling

Designed for long life and consistent accuracy, even during continuous production.

2. Servo-Driven Mechanism

Gives you ultra-smooth motions, accurate bends, and energy efficiency.

3. Programmable Automation

Easily set up complex bending operations with step-by-step control.

4. Auto Wire Feeding & Cutting

Perfect for high-volume production—faster and more reliable than manual feeding.

5. Quick Tool Change System

Ideal for manufacturers running multiple clip or hook designs.

6. Integrated Quality Checks

Advanced options like laser or camera inspection help ensure zero defects.

7. Space-Saving Machine Layout

Compact design fits well in any production floor without major layout changes.

Where These Machines Are Used

Kamtronix bending machines are used across multiple electrical and industrial segments. Typical applications include:

- Electric switchboard clips

- Panel board hooks and latches

- Spring clips for switchgear

- Retainer clips for consumer electrical products

- Wire forming components used in control panels

Manufacturers appreciate the flexibility these machines provide, especially when dealing with custom or varied clip designs.

Benefits of Using Kamtronix Machines

Here’s what manufacturers usually highlight after switching to a Kamtronix machine:

- Lower Production Costs

Less manual labor, less scrap, more output.

- Better Product Quality

Every clip or hook matches the required specification.

- Faster Delivery Times

High-speed production supports growing demand.

- Less Dependence on Skilled Labor

Automation simplifies complex bending tasks.

- Future-Proof Technology

Easy upgrades and compatibility with automated lines.

By choosing Kamtronix—the trusted Electric Switch Board Metal Clips Hook Bending Machine manufacturer from India—manufacturers gain both performance and peace of mind.

Buying Guide — What to Look for in a Hook Bending Machine

Before you invest, consider these important factors:

- Wire or strip size compatibility

- Type and complexity of bends you need

- Expected production volume

- Time required for changing setups

- Ease of integration with existing systems

- Availability of local service and spare parts

- Total cost of ownership, not just the machine price

Kamtronix provides excellent guidance during machine selection so you get exactly what fits your production needs.

Conclusion

If you’re searching for a reliable and high-performance machine to produce electric switchboard clips and hooks, Kamtronix Automation is a name you can trust. As a leading Electric Switch Board Metal Clips Hook Bending Machine manufacturer from India, they deliver machines built for accuracy, durability, and long-term value.

Whether you’re scaling up or refining your production quality, a Kamtronix bending machine can make a noticeable difference in performance and profitability. To understand which model suits your needs best, consider sharing your clip drawings or specifications with Kamtronix for personalized guidance.

No Comments