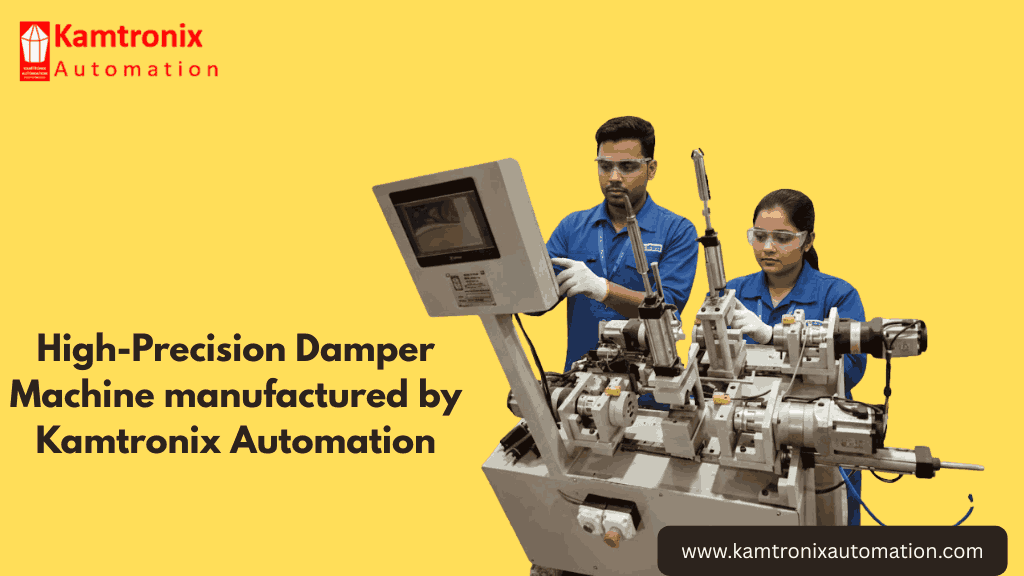

09 Dec High-Precision Damper Machine Manufactured by Kamtronix Automation

Kamtronix Automation — Precision, Reliability & Growth | Damper Machine Exporter from India

Introduction

In HVAC, automotive, and industrial airflow systems, dampers are small parts that carry big responsibility. They regulate airflow, improve efficiency, and ensure safe operations across countless applications. When a manufacturer needs repeatable precision and production speed, they look for a partner who understands both the metalworking and automation necessary to deliver reliable dampers at scale. That partner is Kamtronix Automation — a specialist and proud Damper Machine Exporter from India. In this post, we’ll explore why Kamtronix is trusted worldwide, the technology behind its machines, practical case studies, and how to choose the right damper machine for your manufacturing needs.

Why dampers matter — and why machines matter more

Dampers may look simple — flaps, blades, or louvers — but producing them consistently requires accurate cutting, bending, punching, and assembly. Small dimensional errors or incorrect hole placements can lead to poor sealing, noisy operation, and failed compliance tests. That’s why investing in a robust production line — not just standalone tools — is essential.

Kamtronix Automation focuses on delivering complete, integrated production solutions. As a recognized Damper Machine Exporter from India, the company packages machines, process workflows, and automation logic to ensure every damper coming off your line meets spec.

What Kamtronix Automation offers

Kamtronix’s product and service portfolio covers the entire damper production lifecycle:

- Cutting & Shearing Stations: High-precision shears and laser/servo-cutting options for clean edges and tight tolerances.

- Punching & Perforation Units: Accurate hole patterns for rivets, actuators, and sealing strips.

- Profile Bending & Forming: Controlled bending for blades and frames with programmable parameters.

- Welding & Fastening Modules: Spot welding, ultrasonic welding, and automated riveting for strong, repeatable joints.

- Assembly & Testing Lines: Automated assembly stations combined with inline functional testing — leak tests, torque checks, and actuator verification.

- PLC & SCADA Integration: Centralized control, recipe management, and production reporting to improve uptime and traceability.

- Turnkey Plant Solutions: From layout design to commissioning, Kamtronix builds full lines tailored to customer capacity and budget.

These capabilities are why many buyers name Kamtronix when searching for a reliable Damper Machine Exporter from India.

Technology highlights that set Kamtronix apart

Manufacturing dampers efficiently requires a blend of mechanical finesse and intelligent control systems. Kamtronix incorporates several technology strengths into its machines:

- Servo-driven motions for smooth, repeatable movements and reduced mechanical wear.

- IoT-enabled sensors for predictive maintenance and real-time quality alerts.

- Quick-change fixtures to reduce changeover time between damper sizes and shapes.

- Modular architecture that lets clients scale from small pilot lines to high-volume production.

- Energy-efficient designs that lower operating costs and environmental impact.

The result is a production line that is faster, easier to maintain, and more cost-effective over its lifecycle — a major reason they are considered a top Damper Machine Exporter from India.

How to choose the right damper machine for your business

When evaluating damper machinery, consider the following:

- Production volume: Pilot, low-, mid-, or high-volume.

- Damper types: Opposed blade, parallel blade, multi-blade, louver, fire/smoke dampers.

- Material mix: Galvanized steel, stainless steel, aluminum, or composite.

- Precision requirements: Tolerances and sealing specs.

- Integration & automation: Do you need PLC/SCADA, traceability, or Industry 4.0 features?

- After-sales & spares: Local support or assured international spares availability.

- Budget & ROI timeline: Total cost of ownership vs. throughput gains.

Kamtronix helps customers map these variables into a tailored solution. Their reputation as a dependable Damper Machine Exporter from India is rooted in practical, ROI-focused consultations.

After-sales, training & global support

Buying a machine is only the beginning. Kamtronix emphasizes long-term partnerships through:

- Installation & commissioning with on-site engineers.

- Operator and maintenance training to build in-house capability.

- Preventive maintenance schedules and remote health monitoring.

- Spare-part kits and priority shipping for export clients.

- Retrofit and upgrade paths to extend machine life and add capabilities.

These services ensure that when you invest in Kamtronix equipment, you’re not just buying hardware — you’re buying operational confidence from a trusted Damper Machine Exporter from India.

Sustainability and efficiency

Modern manufacturing must balance output with environmental responsibility. Kamtronix designs lines that reduce scrap, optimize energy use, and minimize consumable waste. Their machines often include features such as material nesting algorithms for sheet optimization and efficient motors that reduce electricity usage.

Conclusion

Dampers are small but mission-critical components across HVAC, automotive, and industrial systems. Choosing the right production partner makes the difference between scale, reliability, and recurring quality issues. Kamtronix Automation combines engineering depth, modern control systems, and a service-first approach — qualities that make them an ideal Damper Machine Exporter from India for businesses worldwide. Whether you’re launching a pilot line or building a high-capacity plant, Kamtronix offers practical, future-ready solutions built to perform.

No Comments