15 Oct Close-up of a Kamtronix motor rotor assembly machine in operation, showing precision fixtures and rotors being assembled

Kamtronix Automation — Top Motor Rotor Assembly Machine Dealers in Delhi

Introduction

Kamtronix Automation is rapidly earning a reputation among manufacturers and production houses as the go-to name for high-quality motor assembly equipment. If you are searching for dependable Motor Rotor Assembly Machine dealers in Delhi, Kamtronix offers robust machinery, tailored solutions and end-to-end support that meet modern production demands. This post explains what makes Kamtronix stand out, describes the machines and features they supply, and offers a buyer’s guide to selecting the right rotor assembly equipment for your plant.

Who are Kamtronix Automation?

Kamtronix Automation specialises in automated and semi-automated assembly systems for the electric motor industry. Their product portfolio focuses on motor rotor assembly—the critical process that influences motor balance, performance and longevity. Operating through a network of authorised dealers in Delhi, Kamtronix combines engineering expertise, local service presence and flexible financing options so manufacturers can scale production quickly and reliably.

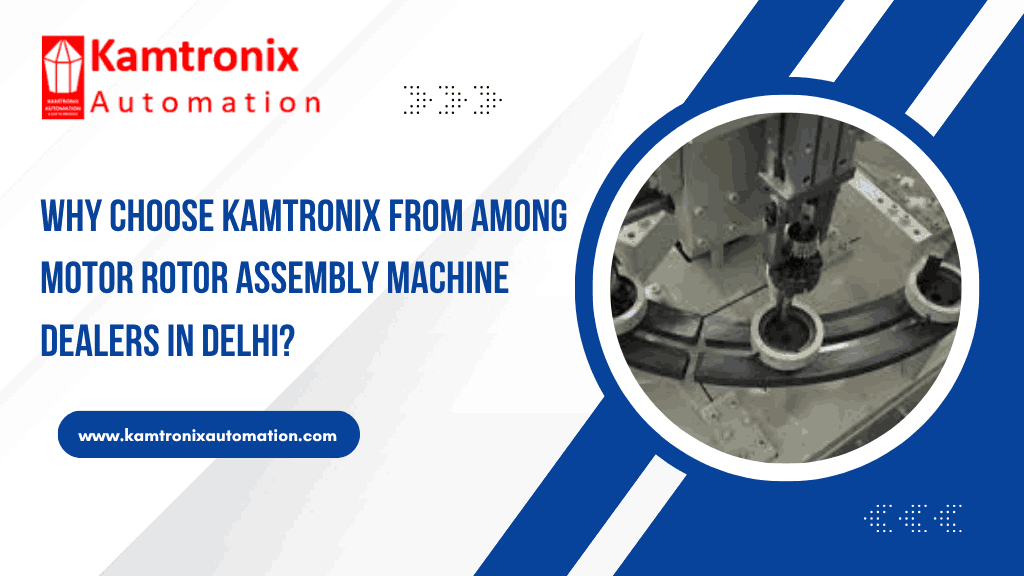

Why choose Kamtronix from among Motor Rotor Assembly Machine dealers in Delhi?

There are several reasons customers prefer Kamtronix:

- Precision engineering: Kamtronix machines are designed to hold tight tolerances during rotor stacking, press-fitting, and riveting—ensuring repeatable performance.

- Local dealer network: Dealers in Delhi provide fast demos, technical consultations and on-site commissioning to get lines running with minimal downtime.

- Customisable automation: Machines can be configured for small-batch flexibility or high-speed continuous production.

- After-sales service: Spare-part availability, preventive maintenance plans and trained service engineers reduce lifecycle costs.

- Compliance and safety: Systems meet industrial safety norms and can be adapted for specific factory standards.

Core products and typical features

Kamtronix offers a range of rotor assembly solutions that span the typical needs of motor manufacturers:

1. Rotor Stacking Machines

Used for accurate stacking of laminated rotor cores. Key features: precise axial alignment, programmable stacking heights, anti-vibration fixtures and quick-change holders for different rotor sizes.

2. Press-Fit & Insertion Stations

For inserting shafts, bearings and retaining components with controlled force profiles. Features include servo-driven presses, force-feedback sensors and multiple programmable force curves to protect delicate components.

3. Balancing and Testing Cells

Dynamic and static balancing integrated with automated correction. Machines include high-resolution sensors, auto-correct algorithms and report generation for quality traceability.

4. Riveting & Welding Units

For securing rotor laminations, rivets and end-plates using mechanical or micro-welding approaches. Tools are designed to deliver consistent joint strength and minimal thermal impact.

5. Complete Rotor Assembly Lines

Turnkey solutions combining stacking, press-fit, riveting, balancing and inspection into a compact production cell with conveyor integration and PLC controls.

Applications and industries served

Kamtronix rotor assembly machines are suitable for a wide range of applications:

- Electric motors for appliances, pumps and compressors

- Automotive traction and auxiliary motors (low-voltage & specialized rotors)

- Industrial motors for pumps, blowers and fans

- Motor repair and rewind shops needing dependable replacement part assembly

- Motor manufacturers transitioning from manual to automated assembly

Buying guide — how to choose the right rotor assembly machine

When selecting equipment through Motor Rotor Assembly Machine dealers in Delhi, consider these factors:

- Volume and throughput requirements — match machine cycle times and buffer strategies to your production targets.

- Rotor variety — ensure the machine supports the range of rotor diameters, stack heights and shaft types you produce.

- Precision vs. cost — higher precision machines demand a larger upfront investment but reduce rework and warranty claims.

- Service and spare parts — prefer dealers who keep critical spares locally and provide trained engineers.

- Integration needs — confirm compatibility with existing conveyors, testing and handling equipment.

- Future scalability — modular machines allow capacity growth without full replacement.

Installation, commissioning and training

Kamtronix dealer teams in Delhi provide complete installation and commissioning services. Typical on-site activities include:

- Site survey and foundation checks

- Electrical and pneumatic hookups

- Machine calibration and test runs with production-sample rotors

- Operator and maintenance training sessions

- Documentation handover including SOPs and spare-part lists

This local presence ensures your line reaches target production efficiently and that staff are competent to operate and maintain the equipment.

After-sales support and maintenance

Kamtronix dealers offer service contracts, preventive maintenance schedules and rapid breakdown support. Typical offerings include:

- Annual calibration and safety audits

- Remote diagnostics and firmware updates where applicable

- Stocked critical spares at Delhi service centres

- Warranty and extended-support packages tailored to production needs

- These measures lower total cost of ownership and keep production disruptions to a minimum.

Cost considerations and ROI

While capital costs vary by configuration, most manufacturers recover investment through:

- Lower labour costs (automation reduces repetitive manual tasks)

- Reduced scrap and rework due to consistent assembly quality

- Faster time-to-market and improved customer satisfaction

- Energy savings from efficient servo systems versus pneumatic-only machines

Request a project-specific ROI analysis from your Delhi dealer — Kamtronix and its dealers typically provide sample calculations based on your product mix and production plan.

Conclusion

For manufacturers seeking reliable partners among Motor Rotor Assembly Machine dealers in Delhi, Kamtronix Automation delivers a compelling mix of precision machinery, local support and scalable automation options. Whether you aim to automate a single operation or install a full production line, Kamtronix dealers can guide you through specification, installation and lifecycle support — ensuring your motor production meets the quality and throughput demands of today’s market.

No Comments