22 Sep Why Kamtronix Automation is the Trusted Foam Cutter Machine Supplier from India for Industries Worldwide

Kamtronix Automation — Foam Cutter Machine Supplier from India

Introduction

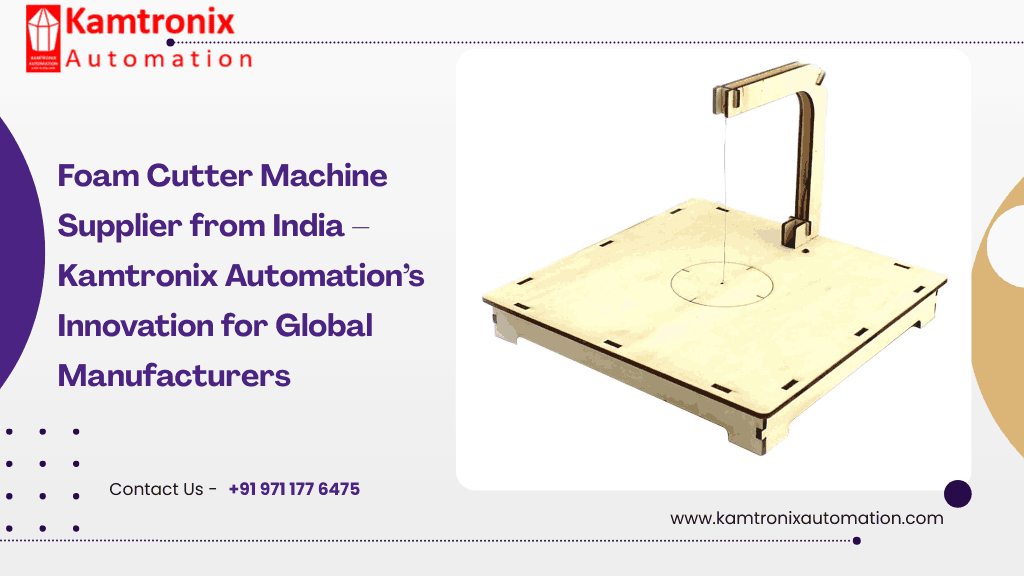

Kamtronix Automation is a renowned foam cutter machine supplier from India, providing a wide range of cutting solutions for manufacturers, artisans and fabricators. Whether you require high-volume CNC foam cutting, hot-wire slicing for insulation panels or vertical cutters for precision parts, Kamtronix supplies machines that combine robust engineering, user-friendly controls and dependable after-sales service.

About Kamtronix Automation

Founded with a vision to bring precision automation to Indian manufacturing, Kamtronix Automation has evolved into a trusted supplier for foam-cutting equipment. With a focus on research and development, the company crafts machines that meet international standards while being optimised for the Indian market — offering cost-effective, durable and easy-to-maintain solutions.

Key Features & Technical Advantages

Kamtronix machines are engineered with features that prioritise productivity and longevity:

- Precision control: High-resolution encoders and servo systems deliver consistent, accurate cuts.

- User-friendly interfaces: Touchscreen controllers with visual programming minimise training time.

- Versatile cutting methods: Hot-wire, mechanical blades and CNC routing options to handle diverse materials.

- Energy efficiency: Modern drives and optimised heating elements reduce operational costs.

- Safety & compliance: Emergency stops, guarding and CE-style safety features for operator protection.

- Easy maintenance: Modular designs make routine servicing straightforward and reduce downtime.

Why Choose Kamtronix as Your Foam cutter machine supplier from India

Selecting the right supplier can make all the difference. Kamtronix stands out because:

- Local expertise: Deep understanding of Indian manufacturing requirements and raw-material variations.

- Customisation: Machines can be adapted for size, speed and cutting method to match your workflow.

- Competitive pricing: Cost-effective pricing without compromising build quality.

- After-sales support: Comprehensive installation, operator training and prompt spare-parts supply.

- Warranty & service: Robust warranty terms and a network of service technicians across India.

- Turnkey solutions: From machine supply to software integration and process optimisation.

How to Choose the Right Foam Cutter Machine

Choosing the correct machine depends on several factors:

- Material type: EPS, XPS, PU or composite foams each behave differently; hot-wire is ideal for EPS/XPS, while CNC routing suits PU and composite cores.

- Thickness & density: Heavier and denser foams require sturdier frames and more powerful drives.

- Production volume: For high throughput, consider panel or vertical cutters; for intricate shapes, CNC multi-axis cutters are best.

- Accuracy & finish: If surface finish is critical, choose machines with fine control over speed and heating.

- Budget & ROI: Evaluate lifetime costs — energy, maintenance, tooling and downtime — not just the upfront price.

Installation, Training & After-Sales

Kamtronix offers a full suite of services to guarantee uptime and operator competence:

- On-site installation: Professional installation and calibration ensure machines run at peak performance.

- Operator training: Practical training sessions to reduce mistakes and improve productivity.

- Preventive maintenance plans: Scheduled visits and remote diagnostics to catch issues early.

- Spare parts & retrofits: Easy access to original parts and optional upgrades to extend machine life.

- Remote support: Phone and online troubleshooting to resolve common issues quickly.

Environmental & Operational Benefits

Investing in the right foam cutter machine helps the planet and your bottom line:

- Waste reduction: Precise cutting reduces scrap and material costs.

- Energy savings: Efficient heating elements and drives lower electricity consumption.

- Recyclability: Clean cutting methods maintain material integrity for recycling.

- Safer workplaces: Automated processes reduce manual handling and injuries.

Buying & Delivery Options

Kamtronix supports flexible procurement models:

- Direct purchase: Standard machines ready for dispatch.

- Custom orders: Tailored machines built to specification with lead times discussed upfront.

- Leasing & financing: Financing options available through local partners (subject to terms).

- Installation & commissioning included: Optionally included or available as add-ons.

Conclusion

Kamtronix Automation is a reliable and experienced foam cutter machine supplier from India, offering a wide range of machines, customised solutions and strong after-sales support. Whether you are a small workshop or a large manufacturer, choosing the right foam cutter from Kamtronix can improve product quality, reduce waste and increase throughput. Contact Kamtronix for a consultation and to find the machine best suited to your business needs.

Call to Action: Ready to upgrade your foam-cutting process? Request a quote, book a demo or contact Kamtronix Automation today to discuss your requirements and discover how their foam cutter machines can transform your production.

No Comments