04 Oct Kamtronix Automation: Advanced Glass Manufacturing Machines

Kamtronix Automation: Leading Machines Provider for the Glass Manufacturing Industry

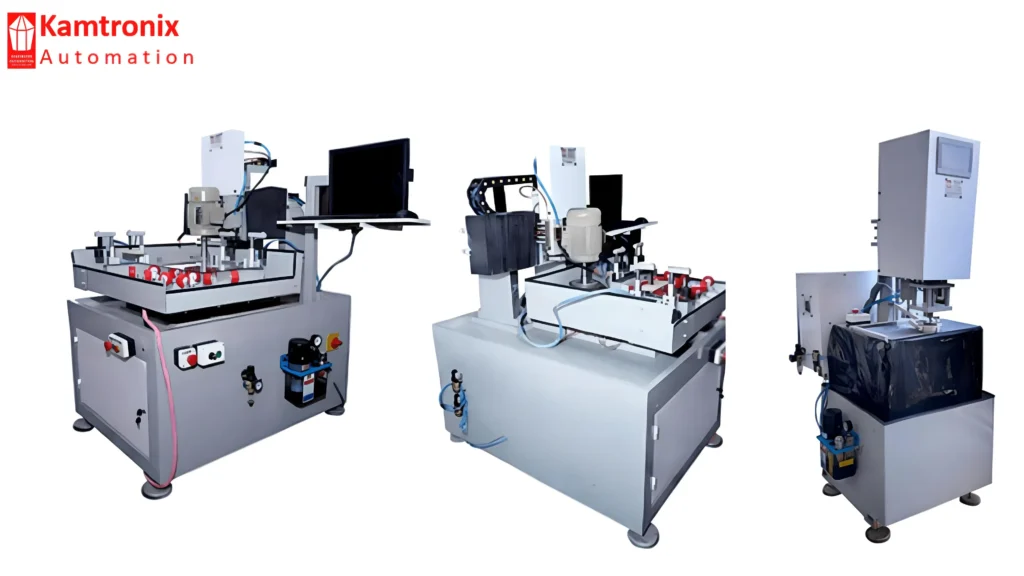

Kamtronix Automation: Revolutionizing the Glass Manufacturing Industry with Innovative Machines

The Glass Manufacturing Industry is constantly evolving, and companies that want to stay ahead of the competition need cutting-edge technology and machines. Kamtronix Automation, a leader in automation technology, provides state-of-the-art machines specifically designed to enhance the productivity and quality of glass manufacturing processes. From automated cutting systems to high-precision polishing machines, Kamtronix Automation has become a go-to partner for glass manufacturers worldwide.

Why Kamtronix Automation is the Best Choice for Glass Manufacturing Machines

Kamtronix Automation isn’t just another machinery provider; it’s a company that understands the unique challenges of the glass industry. Their team of experts continually pushes the boundaries of innovation, developing machinery that offers higher efficiency, precision, and reliability. Below are the key reasons Kamtronix Automation has solidified its position as a leader in the glass manufacturing industry.

1. Expertise in the Glass Manufacturing Sector

Kamtronix Automation has years of experience providing specialized machinery solutions tailored to the glass industry. Their deep understanding of the intricacies of glass production allows them to create machines that meet the unique needs of this industry.

2. Comprehensive Range of Machines

Kamtronix offers a wide variety of machines designed for different aspects of the glass manufacturing process. These include:

- Glass Cutting Machines: These machines ensure clean and precise cuts for all types of glass.

- Glass Polishing Machines: For high-quality finishing and improved transparency.

- Glass Tempering Machines: Essential for strengthening glass and making it more resistant.

- Glass Drilling Machines: For accurate drilling without cracking or damaging the glass.

- Glass Edge Grinding Machines: For smoother edges and a professional finish.

3. Superior Automation and Technology Integration

Kamtronix Automation leverages cutting-edge technology to deliver fully automated solutions. Automation not only speeds up the manufacturing process but also reduces human errors, ensuring higher product quality and consistency. Their machines are equipped with the latest digital controls, allowing for seamless integration into existing production lines.

4. Customization to Fit Unique Business Needs

Every glass manufacturing plant is different. Kamtronix offers customization services to modify their machinery to meet your specific production needs. Whether it’s adjusting the size, speed, or functionality of a machine, Kamtronix works closely with clients to deliver a solution that perfectly fits their operations.

5. Durable and High-Quality Machines

Kamtronix Automation is known for providing durable machines that require minimal maintenance. Built with robust materials, their machines are designed to withstand the high demands of industrial glass manufacturing while maintaining optimal performance over time.

6. Improved Energy Efficiency

Glass manufacturing can be an energy-intensive process, but Kamtronix Automation machines are designed with energy efficiency in mind. Their machines reduce power consumption without sacrificing productivity, helping manufacturers save on energy costs.

7. Exceptional After-Sales Support

One of the standout features of Kamtronix Automation is its commitment to customer service. They offer comprehensive after-sales support, including maintenance, training, and troubleshooting, ensuring that your machines continue to perform at peak efficiency.

The Advantages of Choosing Kamtronix Automation

1. Innovation and Technology

Kamtronix Automation continuously invests in research and development to ensure their machines are at the forefront of technological advancements. This innovation allows them to provide glass manufacturers with machines that improve productivity and ensure the highest standards of quality.

2. Customization Options

Every glass manufacturer has unique requirements. Kamtronix offers customizable solutions that cater to specific manufacturing needs, whether it’s for architectural glass, automotive glass, or specialized glass products.

3. Global Reputation

With clients across the globe, Kamtronix Automation has built a reputation for reliability, quality, and excellent customer service. Their machines are used by some of the largest glass manufacturers in the world.

4. Sustainability

Kamtronix is committed to sustainability. Their machines are designed to minimize energy consumption and reduce waste, helping glass manufacturers meet their environmental goals.

Conclusion

Kamtronix Automation is undeniably a leader in the glass manufacturing industry, providing state-of-the-art machinery that enhances precision, efficiency, and quality. Their commitment to innovation, sustainability, and customer satisfaction makes them the top choice for manufacturers worldwide. If you’re in the glass manufacturing sector, investing in Kamtronix Automation’s machines will undoubtedly elevate your production processes to new heights.

Kamtronix Automation stands out due to its commitment to innovation, customization, and customer satisfaction. Their machines are designed for precision, efficiency, and reliability, making them the preferred choice for glass manufacturers globally.

Yes, Kamtronix offers a range of customizable solutions to meet the unique needs of various glass manufacturing processes, ensuring optimal performance for specific applications.

Kamtronix’s glass tempering machines use advanced heating and cooling technologies to strengthen the glass, making it resistant to breakage and ensuring it meets safety standards for various applications.

Absolutely. Kamtronix Automation designs its machines to be energy-efficient, reducing overall production costs and helping manufacturers achieve their sustainability goals.

Yes, Kamtronix offers comprehensive after-sales services, including installation support, training, and maintenance services to ensure their machines perform optimally.

No Comments