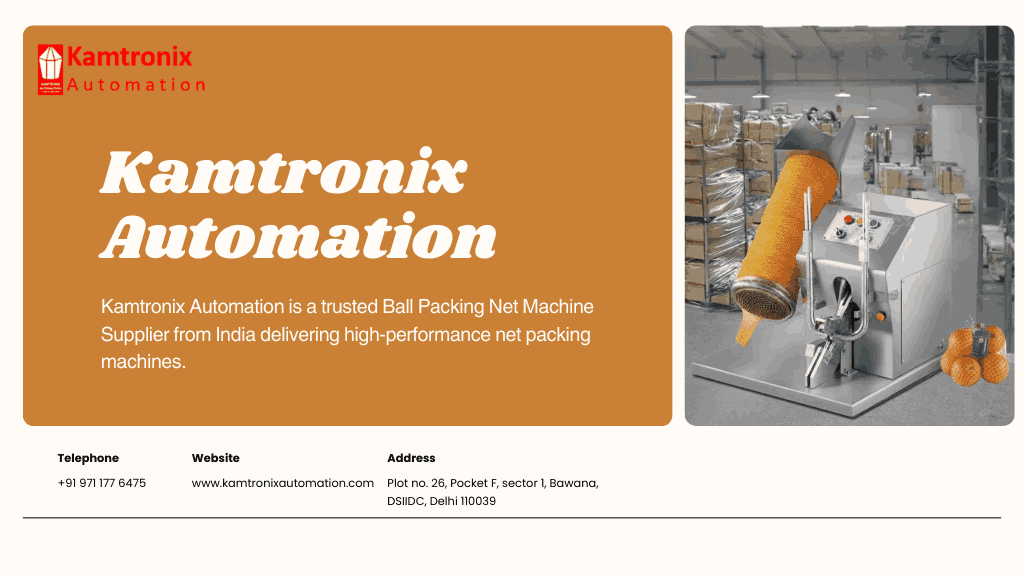

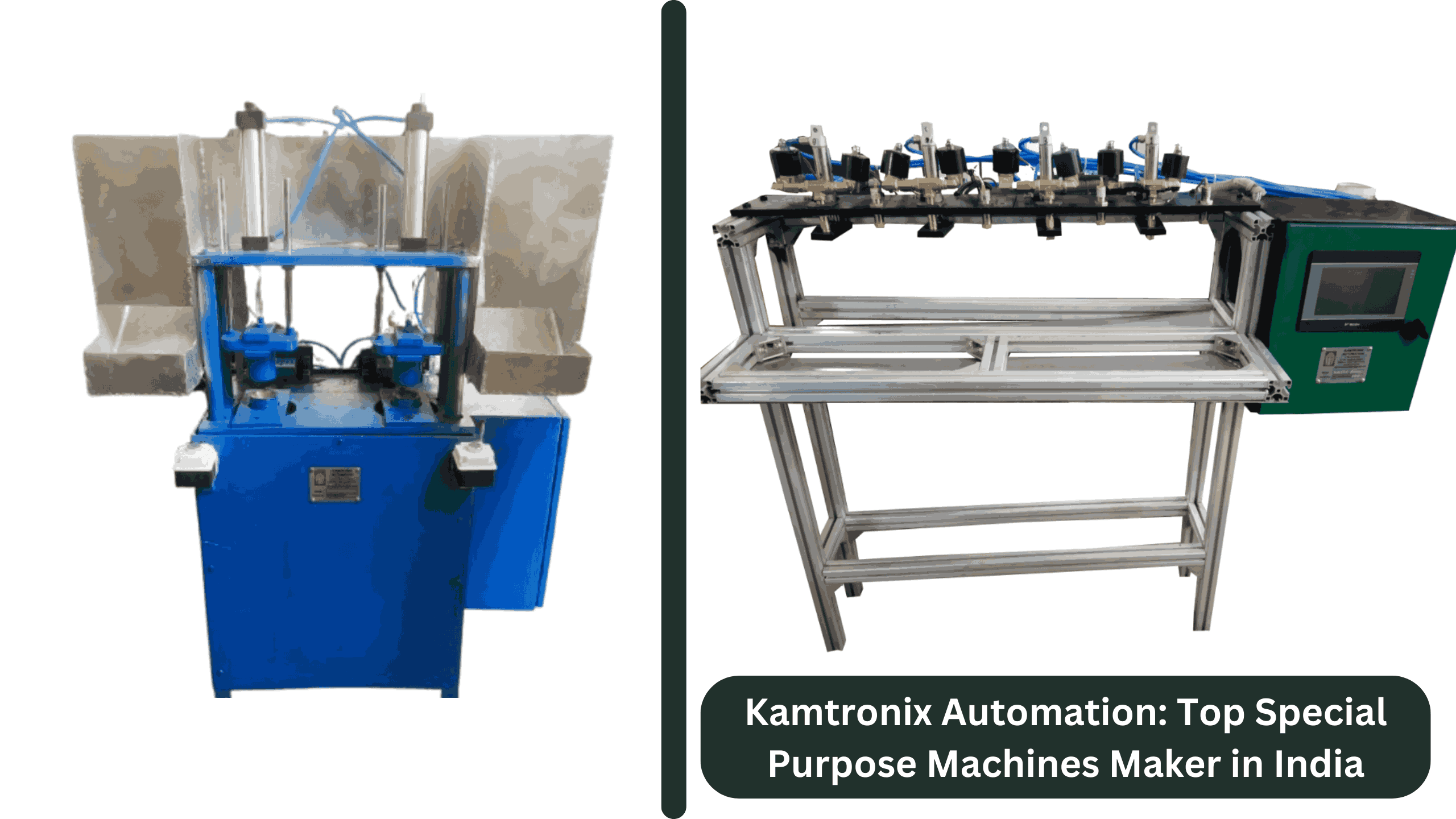

Kamtronix Automation – Leading Ball Packing Net Machine Supplier from India

Kamtronix Automation – Top Ball Packing Net Machine Supplier from India Providing Energy-Efficient Packaging Machinery Introduction In today’s competitive manufacturing landscape, efficiency, automation, and precision define business success. Industries such as sports goods, toy manufacturing, food packaging, and industrial product packaging require reliable machinery that...