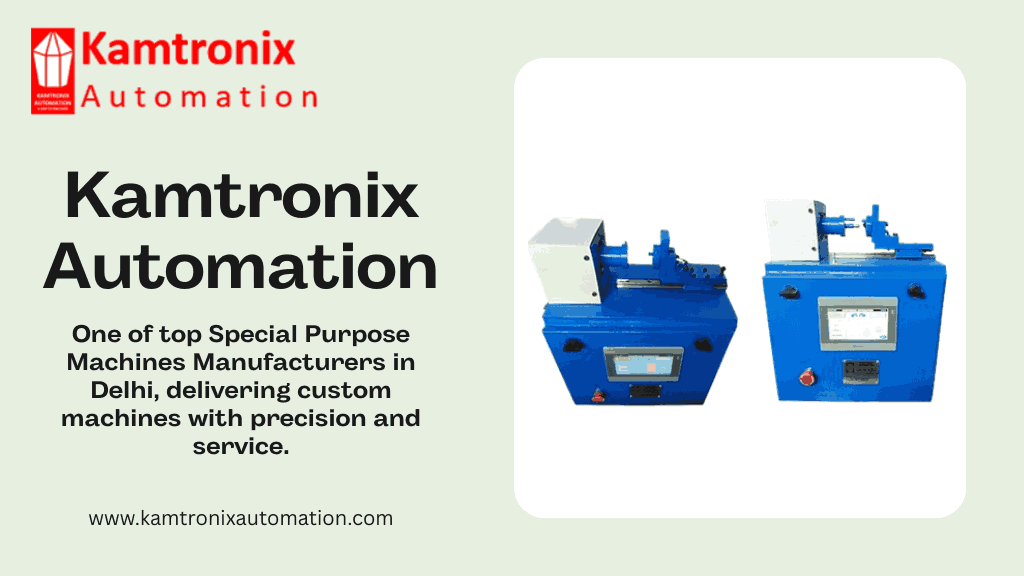

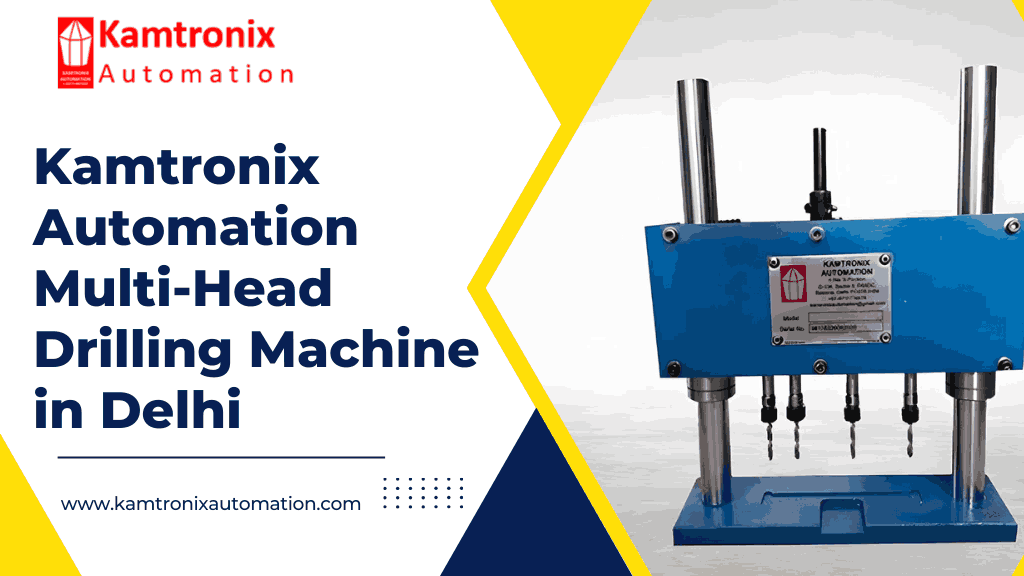

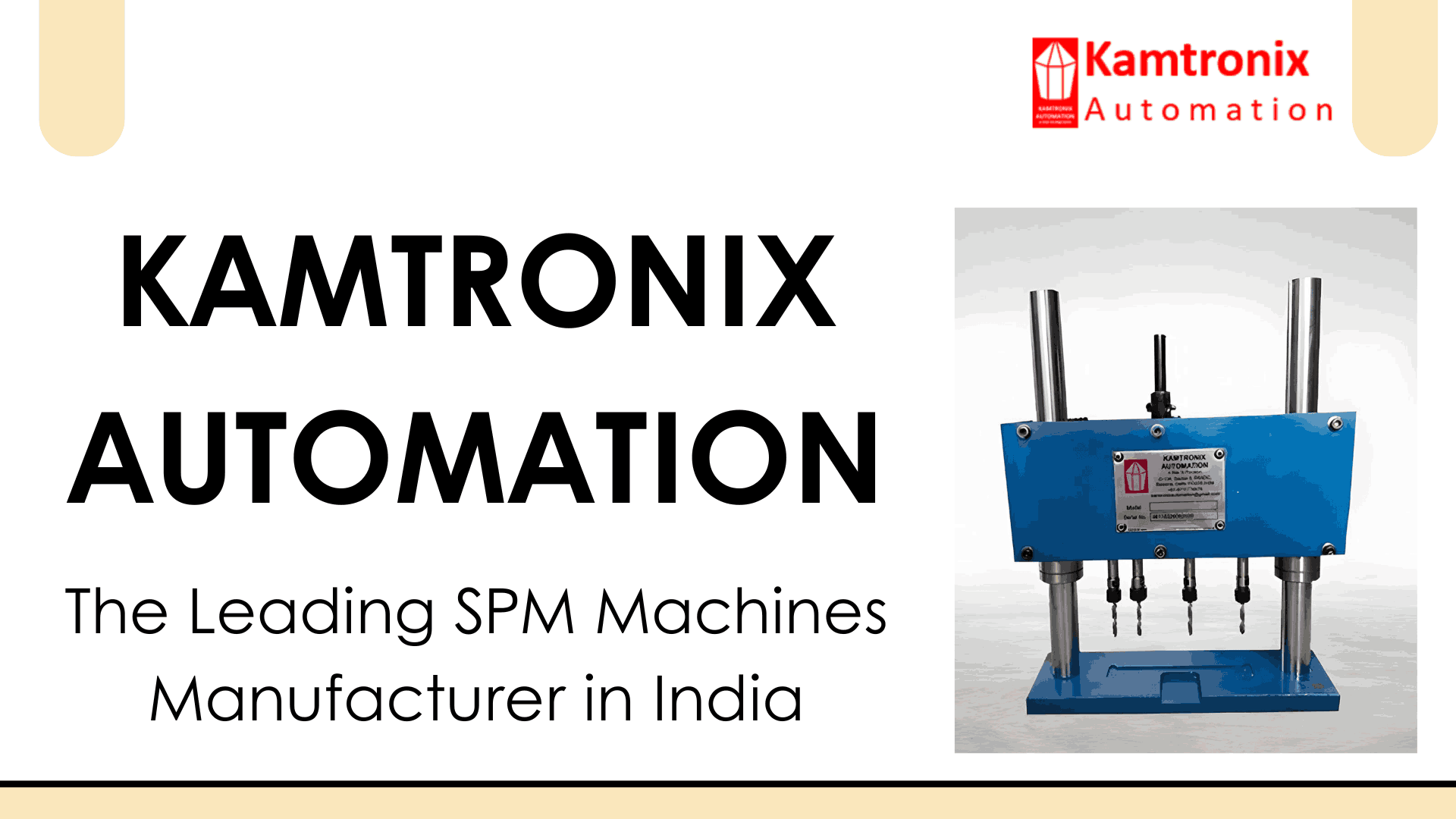

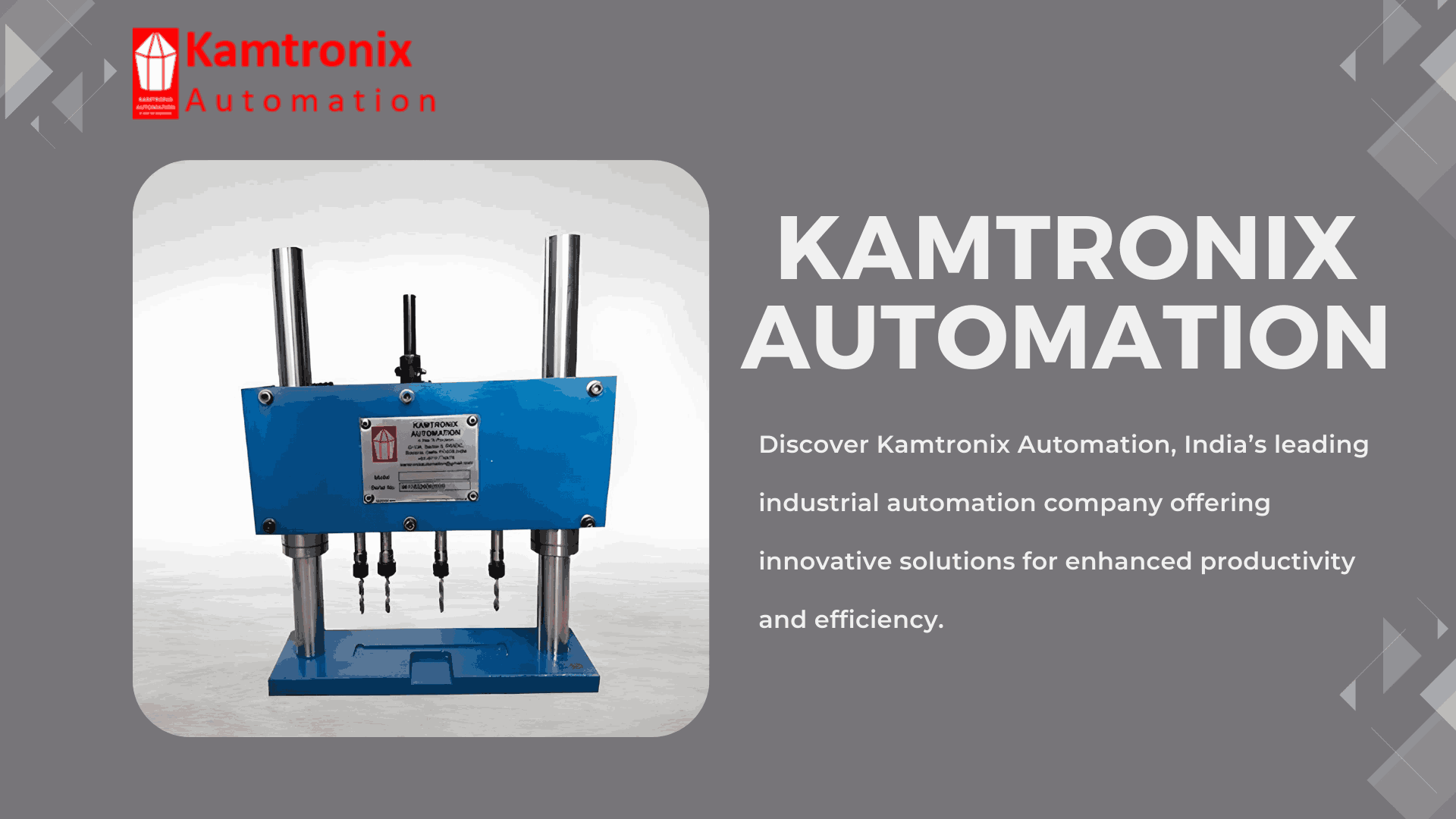

Trusted Manual Industrial Drill Machine Manufacturer in Delhi with Customer-Focused Design

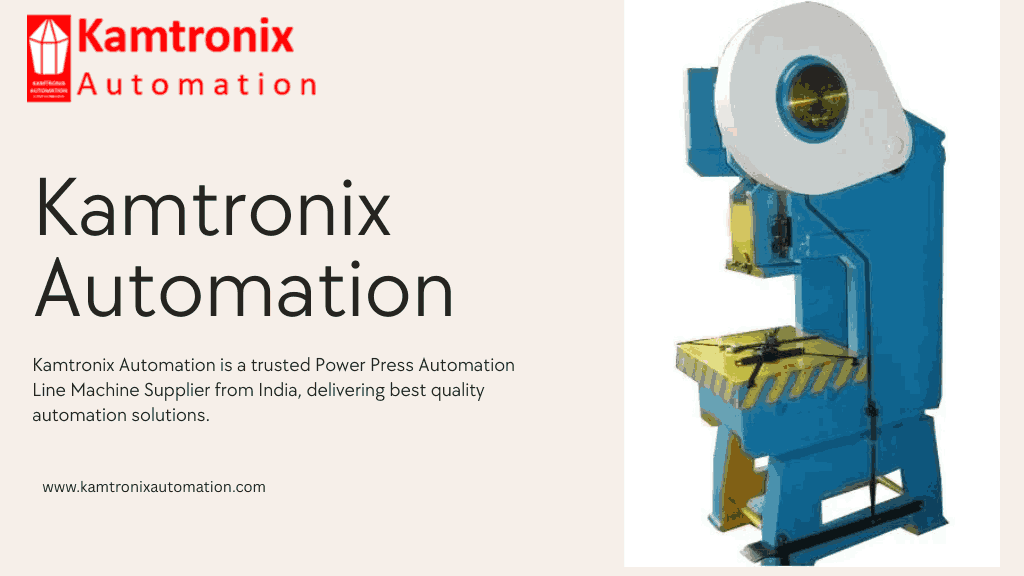

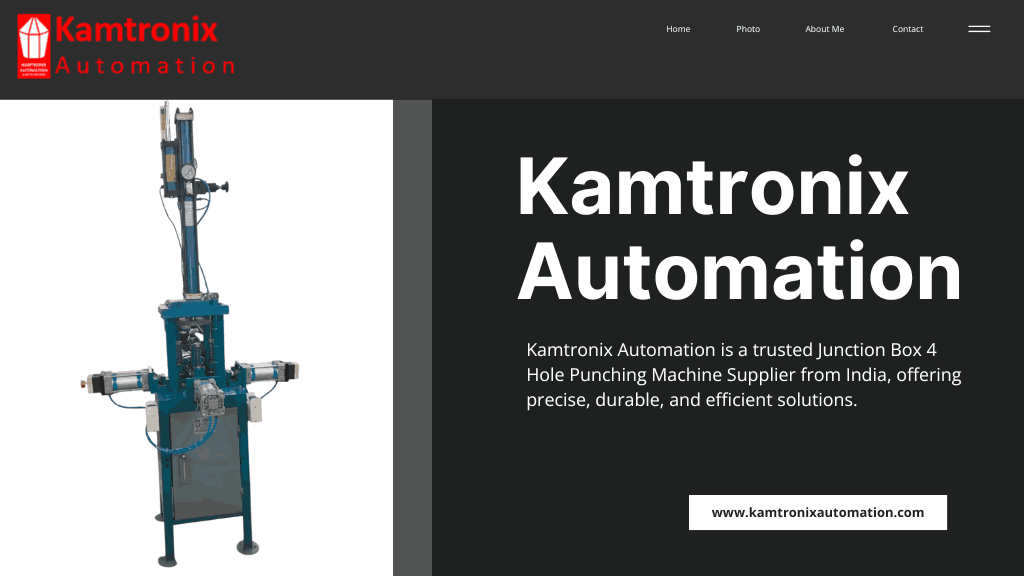

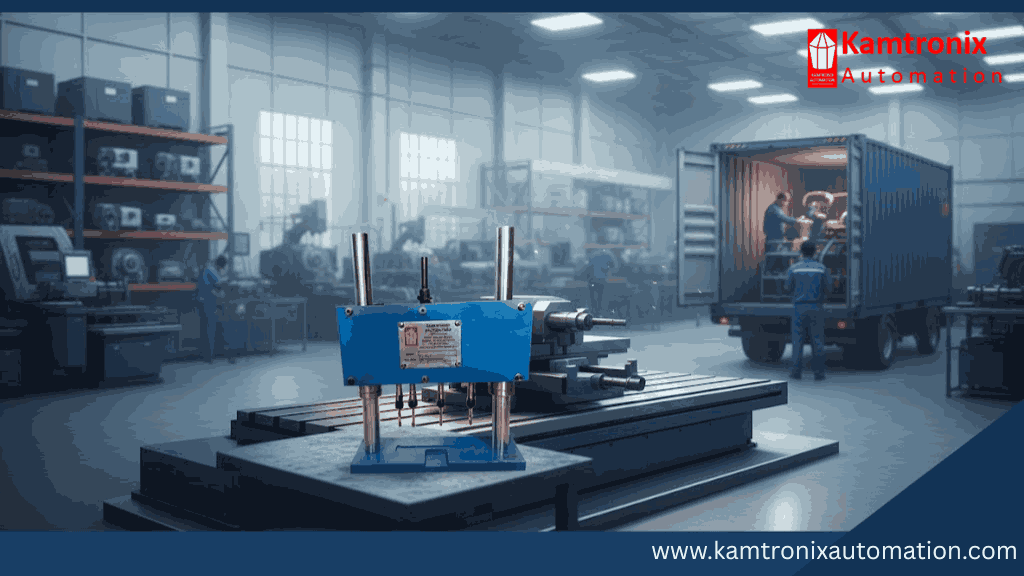

Kamtronix Automation – Trusted Manual Industrial Drill Machine Manufacturer in Delhi Introduction In today’s fast-paced manufacturing and fabrication industries, precision, durability, and reliability are essential. Industrial drilling machines remain a backbone for workshops, factories, and production units where accuracy and efficiency matter the most. Kamtronix...